Solid Grinding

Reduction of the original particle size

to a smaller granularity.

We have different pin mills to meet your grinding needs, reaching up to 50 microns.

Likewise, we can perform various cuts of the product, according to desired particle size ranges, rejecting the percentage that does not meet the required specifications.

Our mills allow us to incorporate liquid nitrogen to perform cryogenic grinding, i.e., reducing the original particle size to a smaller granularity, at a controlled temperature or by pre-freezing the product, in order to increase its hardness and fragility.

Grinding can be for the final product or raw materials that require a specific granularity for subsequent services, such as mixing and/or packaging.

Grinding batches can be a minimum of 25 kg. to any higher quantity, as the mills have a continuous feeding system.

Our semi-automatic packaging lines allow us to adapt to the needs of our clients.

We can package in different formats, according to your needs:

-

Big Bags in different capacities

Big Bags in different capacities

-

Bags paper/plastic/raffia, both open and valve, also stitched and/or heat-sealed

Bags paper/plastic/raffia, both open and valve, also stitched and/or heat-sealed

-

Drums or buckets Kraft, plastic, etc.

Drums or buckets Kraft, plastic, etc.

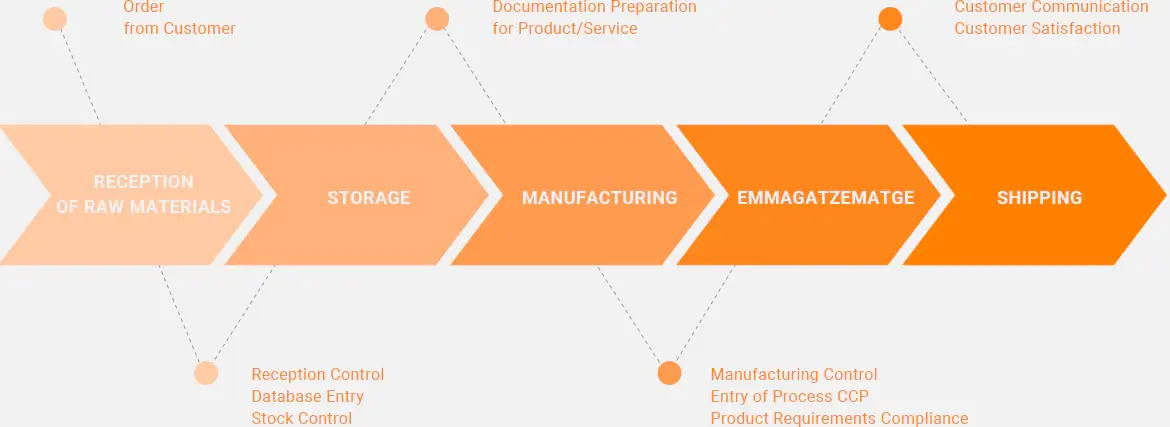

Our internal quality system controls, measures, and verifies all phases of the process, from the reception of raw materials to the dispatch of the finished product, with special control of CCP.